Hi. I needed to remove the front caliper from my 2022 V7 Special so I could take out the fork leg. What I hadn’t realised was that Moto Guzzi had fitted the caliper using bolts made of cheese. They were a Torx head type but the Torx socket was very poorly formed. I used the correct Tork bit, tapped it home with a hammer to ensure it was seated properly and attached an 18 inch ratchet handle. On applying pressure to the ratchet, the Torx bit just turned in the head of the bolt and chewed up the socket. I managed to get the bolts out after a lot of effort but now I need to get replacements. Does anyone know if there are better quality bolts available? If not I guess I’ll just need to fit some more genuine Moto Gorgonzola cheese ones.

Thanks

Tony

I’m sure there are lots of suppliers out there however I found these people very helpful when I contacted them about my V85 and replacement bolts https://raceboltuk.com

They don’t specifically list the MG brand at the moment but seemed very keen to get involved. It was a chap called Phil I spoke with.

Thanks Bob, I’ll give them a call.

Regards

Tony

That’s strange, we have two 2022 V7 Stones and on both the caliper is fastened to the fork with hex bolts. I wonder why they would be different on the special ?

Torx heads are way better than hex heads for cap heads as long as the bolt material is of good quality. It’s much easier to round off a hex head compared to torx.

I use Westfield fasteners, Kayfast & GWR fasteners for most of my fastener requirements

Racebolt for exotic materials such as Titanium bolts, but for stainless or regular materials always the above listed

Arrrgh something else to check! ![]()

Thanks Guzzimax. I’ll get in touch with those guys. I’d like to get stainless as the OEM bolts seem like they may have lightly corroded into the fork leg thread, thereby making extraction more difficult.

Regards

I purchased torx head stainless bolts for the calipers on one of my V11s & Griso last year. I’ll check where I sourced these from and let you know.

Whilst I remember using Racebolt for Titanium bolts for the discs & calipers on my MT01, I don’t know what moment of madness led me to thinking saving a few grams on using titanium bolts on a bike weighing 265 kgs with a 15 stone rider would have any effect on its performance ![]()

Stainless is the way to go

Thanks Guzzimax. I’d definitely like to know where you got those as I’ve searched the internet and can’t find any.

Regards

Tony

Some people do say that stainless is more liable to shear failure when used for an application like mounting calipers, hence the recommendation to use titanium.

Personally, I see little chance of 10mm of stainless steel suddenly shearing off due to normal braking forces on the road. I have replaced all the caliper mounting bolts on my bikes with stainless allen head bolts.

Me too ![]()

A couple of thoughts here.

Are you sure they’re Torx ? Textron came out with Torx Plus, arguably to continue their patent protection as Torx expired. I’ve found BMW ended up sourcing some Torx Plus screws for brake master cylinders by mistake. They look similar and a Torx bit will appear to fit in a Torx Plus socket, but the contact area is small and any degree of real torque will strip it. The resulting hole tends to look like an Allen socket. When intact, Torx looks like a six-pointed star, whereas Torx Plus looks like a six-toothed gear wheel. I ordered a set of four master cylinder screws as genuine BMW spares and when they arrived, two were Torx and two Torx Plus. So it can happen.

But your damage is now done.

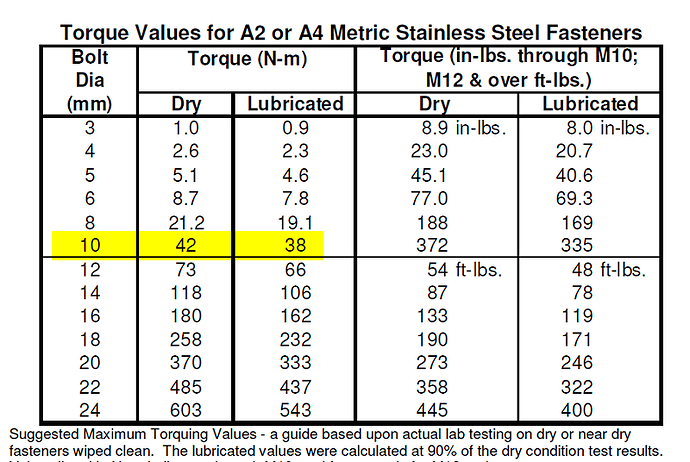

One of the issues with stainless fasteners is they aren’t High Tensile. If you look at the head of a stainless bolt, there’ll be a marking on the top. A2 - 70, is typical.

A2 is the grade of s/s, we really only see A2 and A4, interchangeable for our purposes.

The 70 refers to the tensile strength ( I can’t remember but I think it’s MPa ) of that particular bolt as modified by heat-treatment or mechanical forming. You can get A2 - 80; these are equivalent to a grade 8 High Tensile bolt. I’ve not found anything greater than 80 available in s/s; at least not to people like us.

On my calipers and discs I try to use 80 grade s/s, but everyone’s right, even a 70 is only 12% lower tensile stress than an 8 grade bolt so the safety margin calculated by the engineers should be way high enough for it to make little difference. However, if the application needs a 10 or 12 grade fastener, as in 10.9 or 12.9 stamped on the head of the HT bolt, then that’s different. You’d be eating into that margin by fitting what is effectively a 7 grade bolt. But really, the shear is taken by the friction and that depends on the torque setting used to tighten the bolt. If the bolt is specified to be able to take the appropriate torque setting, then it’ll hold in the application.

In practice, I’ve also replaced all my caliper mounting bolts with stainless.

As a supplier, I’ve found Accu to be very good and they supply excellent specification documentation on their website.

Oh, and you may already know this, but be aware that a lot of manufacturers stop using standard metric fasteners once they reach 10mm. You may find that those caliper bolts are M10x1.25, not standard M10, which is a 1.5mm pitch.

These are usually referred to as metric fine, you can also get M10x1.0 and M10x0.75 but these are not very common. Buy a thread pitch gauge (they are not expensive) and measure the thread pitch of the bolts you are replacing to be sure.

Best wishes

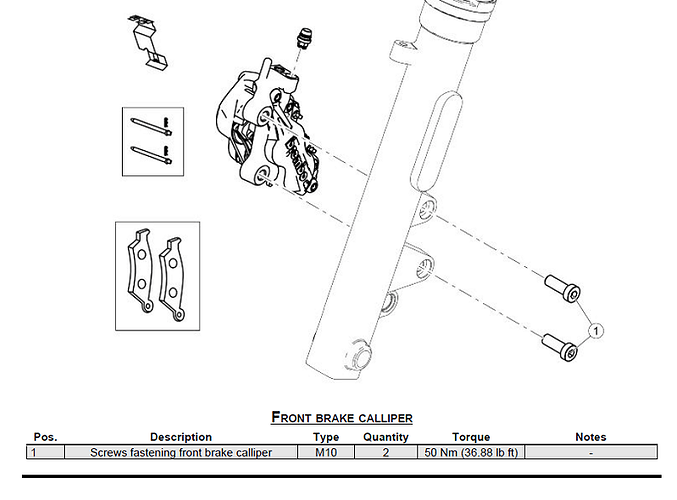

From V7-V9 E5-2021-.pdf

‘Service Station Manual - V7 E5 Special-Stone’

(50 N-m)

And…

Just in case you were thinking of doing them up to the same specified tightness.

![]()

Thanks for that, never heard of it 'til now! ![]()

![]()

Look under cap head bolts in the menu you will find hex and torx heads

Also as someone has suggested in this post, check the thread pitch to verify if it’s metric coarse or fine thread. Don’t assume it’s standard metric (coarse)

Many caliper bolts are metric fine thread

If in doubt get a vernier and measure the pitch

Thanks everyone. I definitely need to check the pitch the bolt pitch does look finer than ‘standard’ 10mm bolts. What’s the difference between the ‘old’ Torx head and new TorxPlus - is it easy to spot the difference? Do you need special bits for TorxPlus or do the old style Torx bits work for both?

Regards

I remember years ago an experienced bike mechanic said avoid stainless for brake Caliper bolts as they lack the tensile strength of steel. I just asked google and this does seem to be the case so be careful. I’m not a mechanical engineer so happy for some feedback on this.

I’ve just checked my '22 850 special and it has Hex head allen bolts for the caliper mounts and torx for the caliper halves !