Well, let’s not make assumptions. We’re all working it out as we go along, but I’m reasonably confident 400mL per leg is too much. Let’s see if Chris comes up with some commentary; he’s very good on this sort of thing.

My guess is you’re hydraulic locking now; if you fully compressed the forks with that much oil I think it’d overflow the top, so not enough airspace.

This might explain leaking oil from the fork seals.

SAE 20 is a good, traditional choice for this vintage machine. Geoff Baines used SAE15 in my Darmah Marzocchis and they feel a bit too solidly damped. I’m going lighter because of modern oil and modern road surface and old bones.

Hello, I used Bremen Autotechnik Motorcycle Fork Oil 20W - 185ml per leg, the forks have 115mm travel.

I hope this helps.

Chris

1 Like

Thanks Chris. Consensus seems to be around 200ml. I’ll drain them.

Probably getting to the point that I need to strip, check and rebuild them.

Thanks

Eddie

As far as I am aware, you will only need to replace the seals, and then only if they are leaking. If the stanchions are damaged you could get them reground and re chromed but this is a lot of work. A cheaper solution is fit fork gaiters, that stop the stone chips on the stanchions.

1 Like

What Chris said…I’m a gaiter chap, myself. With my LM and Darmah, as soon as I replaced/rechromed the fork stanchions I gaitered them up. My '81 Yamaha, gaitered up within a year of coming out of the crate; never had to do anything to the forks except drain and refill.

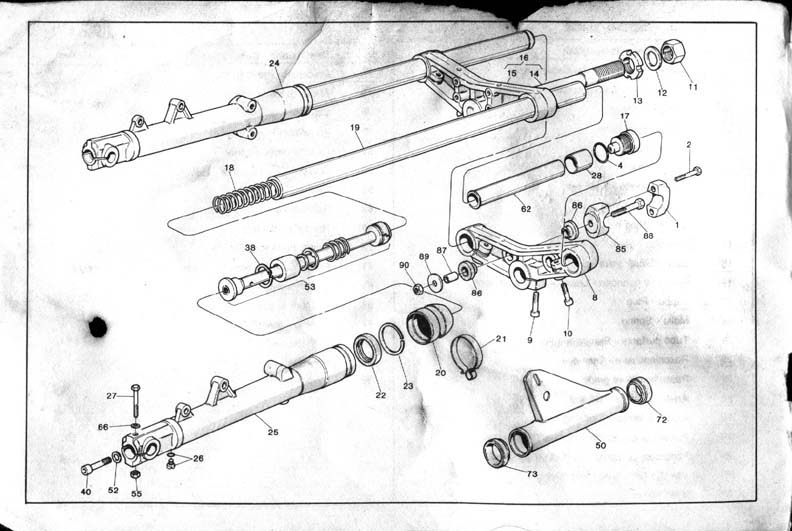

However, if there’s something missing inside your forks, in the damper, causing the ‘clonking’ , the only way you’ll find it is to dismantle, carefully recording where everything came from against whatever parts diagrams you can find.

1 Like

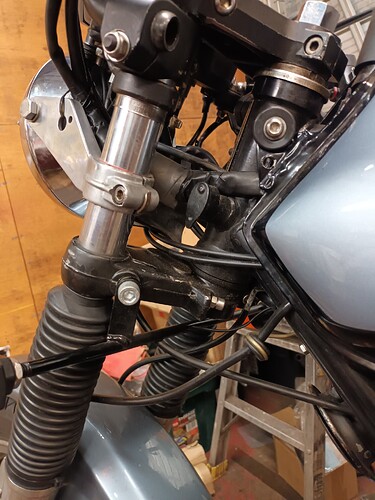

Sorry about the mess in the garage!

Bolts under the front axle holding damper assembly all tight too.

1 Like

Drained off the excess oil so now back to around 200ml.

I found one of the top air bleed off springs missing. Any idea about source for replacing or can I do without?

pushed the forks down a number of times and no strange noises from inside the forks.

Replaced the caps.

I’ll take it for another test ride. Tempted to swap to 10 weight oil if it makes the ride softer.

Thx for all the help

Eddie

2 Likes

Well, that’s sounding much better, that there’re no dodgy noises. I don’t know about the missing spring, but applying my engineering judgement, I’d say, it’d be a good idea to put it in. I reckon with the screws tightened down there should be no air leak, so it should work ok.

I’m finding it tricky seeing what’s on the end of the one spring you found. It should be a 5/32" ball bearing, but that looks a bit odd. Was there a ball in the other side or was that missing, too ?

I was looking at replacement kits for these valves just the other year but they all appear to have gone. I’d try giving mdina-italia a phone call and asking them. You have the parts book page now so you can quote part number at them. Should be 0689.37.470 for the spring, but I’m sure they were selling it as a kit of ball, spring and allen head screw.

Let us know how your test ride goes.

1 Like

I can’t find any of those valve kits but what I did find on mdina italia’s site when looking for the complete fork top assembly was some they’ve got which are modified to allow preload adjustment ( under same part number as standard complete fork top assembly ). This was previously done by varying the length of that top spacer from model to model. They replaced the ball and spring valve with a threaded adjuster and locknut. This would no longer allow the ball and spring action, implying that you should be good to just use your countersunk screws to lock down the fork tops. I’d still release the air though.

1 Like

Good news. I pumped the forks with the allen head screws off and spring out and air was coming out and no clonks (which happened before when pumping and allen bolts tight). So I reckon it was trapped air stopping the forks compressing.

Took it for a ride out this morning- much better, Firm but no clonks on normal bumps.

I think that was the issue. I’ll maybe take the rubber seal off the allen heads and let the air escape when they compress. I may go down the 10 weight to see if that eases the stiffness a bit. I could also make up a pair of slightly shorter spacers to adjust the pre load or check out the Mdina site.

Thanks guys. Think I am on the home straight now.

Eddie

3 Likes

Depends a bit on where the clonk happens - under compression, or on the rebound?

On these forks, as you probably know, the damper is a cartridge inside the fork leg. If the clonk is on the rebound, then the cartridge is weak and not damping the spring rebound correctly. Time for a new cartridge: replace in pairs.

A small amount of oil is required in the fork sleeve, which is purely for lubrication of the leg in the sleeve. This is not for damping: the amount you put into the fork during re-assembly has to be accurately measured with a syringe (for example). Too much, the seals will burst. Not enough, the fork leg clonks hard on the bottom during compression. The oil grade is important, too - not conventional high SAE shock oil.

Sounds to me more like the damper cartridges are getting tired.

These are not standard forks

1 Like

Play around with the oil, mine on the MKIII did not work as they should, - think I used a heavier oil

DAve R