My final drive filler plug has a 3mm hole in it and oil keeps escaping is this correct I don’t remember it on

Shouldn’t be any holes. Previous owner modification?

This is bad.

It leaves the drive open to water ingress. Water in the oil turns it into grinding paste. Best get new filler plug and change oil.

So the next question is has anyone got one without a hole they would like to sell

a glob* of epoxy will block that hole perfectly well until such time as you find a reasonably priced replacement. after cleaning, of course.

*technical term

I thought I’d seen some people do this to put a breather valve into the bevel box. Do some of the later Guzzis have a breather in the plug as standard ?

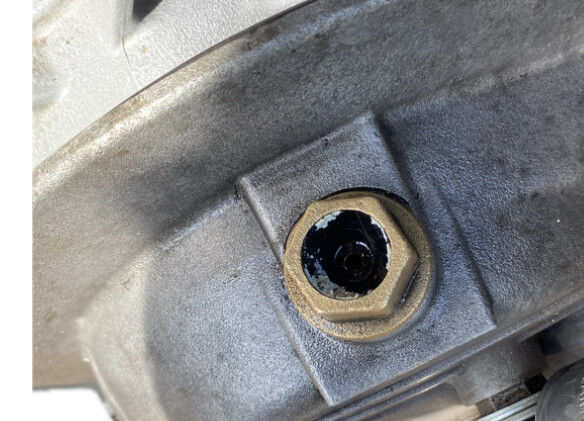

There’s another style of filler plug which is flat with a 10mm hex in it for an Allen key, my LM had these for the FD and gearbox fillers. This photo from Gutsibits…

The advantage with this type of plug is that it has an o-ring, so you don’t need to change the crush washer every time you change the oil.

Shaw stainless make them as well, if you like bling! click here

Interesting I have now removed the filler plug and it has already been filled with epoxy and then re drilled.

I will try filling and closing the plug and see what issues that causes.

the only thing that you might wish to know about, if not already, is ‘burping’:

fill the bevel box with the recommended amount of oil (not until it overflows from the ‘overflow’ hole - why not? separate discussion).

with the recommended volume of the correct oil in the rear drive, ride it for a while, with appropriate spanner in pocket. stop, crack the filler bolt open, supposedly releasing any ‘pressure build up’ (burping), retighten, ride, repeat a couple of times.

does it work? you tell us. certainly doesn’t hurt.

Yes I forgot to mention - it’s pretty neat all said and done, looks good and works well.

+1 for Shaw Stainless. ![]()

Footnote: V7 850 E5 has this style as standard for gearbox filler.

Footnote 2: my understanding is/was, the shaft tunnel is hollow, and there is a small passage bypassing the pinion housing, so the FD can ‘vent’ into the tunnel, which is quite large, so external venting shouldn’t be necessary. However it’s possible the FD to swingarm joint gasket can block the passage, if it doesn’t have the cut-out for it.

EDIT: actually, might be the gasket between pinion housing and case that needs the cut-out - been a long time since I had mine apart. Whaever, there was a small channel connecting FD internals to driveshaft tunnel.

I have tapped the hole and screwed a grub screw in to seal it been out and got everything hot and it all seems good.

Thanks everyone for your assistance.