Evening All,

I am currently restoring a 1970 Ambassador (US version) and I’m having trouble setting the ignition (I believe). I did a complete overhaul of the engine - most of it it did it myself, but got a machine shop to press small ends, re-machine surfaces of heads, fit new valve guides, grind valve seats and polish the crankshaft. Some time ago I found a Gilardoni pistons and barrels set for a V7 Sport (it was the only set I could find on internet at that time and I bought it) - I know the piston is 0.5 mm smaller in diameter compared to the Ambassador, however since it’s a set I didn’t think it was an issue. Another important modification is that I got the camshaft refurbished by Joy Engineering, however the only profile they could do was a B10. I’ve read of some big twins being ok with it (however I am very ignorant on this topic).

I left the valve timing as the original (aligned the paint marks on the gears and pin), I did the valve clearances as per the manual, did the ignition timing as per Guzziology (static timing (second) mark, compression stroke of left (starter motor side) cylinder) and set up the Dell’Orto VHB 29C carbs (I took them apart and cleaned them with an ultrasonic cleaner and reassembled with new seals) as per Carburetor - setting them up - Loop frames - Moto Guzzi - Topics - Gregory Bender.

I did a quick compression test and found it to be 125 PSI exact on both sides. Not sure it this is ok considering these are new barrels, pistons and rings?

I have primed the oil pump before firing the engine by undoing one of the banjo bolts that feeds the oil into the headers.

I can get the engine to fire up very irregularly and it dies after a couple of backfires.

I’d be grateful if you could help me understand how to take it from here please. Do I need to do something different considering I now have B10 lobe profile on the camshaft?

Thanks!!

Rob

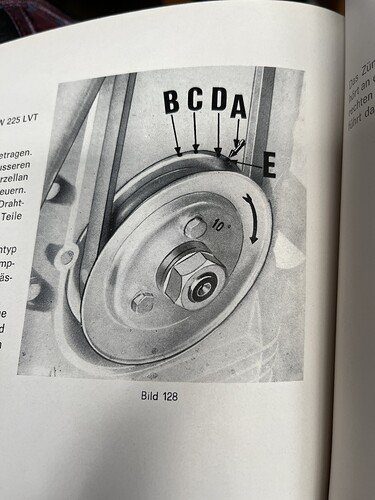

I can’t comment on the camshaft, but are you using the timing marks on the front pulley? You may have already checked this, but are they aligned to the crankshaft properly? There are 3 holes and nothing to index them so it’s possible to get them 120 or 240 degrees out. In my case, the engine would run but very badly.

Ian

Hi Ian, thanks for the reply. I’ve mounted the pulley on the position where I could see (from plug hole) TDC of left (second) piston and the arrow coincided with TDC mark of the pulley. And did the timing when that same piston was compressing (checked it by leaving my finger on the plug’s hole whilst turning the engine.

Sounds right. According to my book the engine runs clockwise when looking from the front so the TDC mark (B) is the leftmost one when looking from the front.

I usually use a strobe on mine and set it to the full advance mark at 3000rpm, although it seems quite tolerant to a bit of variation.

Condenser OK? There are loads of dodgy ones out there, so I use NOS ones for cars. Easy enough to mount on the outside of the distributor.

Ian

Thanks Ian.

Not too sure what you meant with the strobe at 3000 rpm - I guess that’s for the dynamic timing? I did the static timing at position C.

The condenser is a new Magneti Marelli, which I bought from Stein Dinse, I believe. I also got a new cap, rotor and points. I have set the points gap to 0.45 mm.

B is TDC position

C is 10 degree advance at idle

D is partial advance, 30 degrees at 2200rpm

E is full advance, 38 degrees

I think those are the right numbers for a 700/750 version. Mine is an 850 so has a different advance curve.

I use the strobe and make sure the timing hits the full advance position correctly. My reasoning is that it’s where the engine spends most of it’s working life.

If you have a multimeter with a capacitance setting I would suggest checking the condenser.

I had have 2 brand-new ones fail, one of which was a Magneti-Marelli item although probably bought from one of the UK suppliers.

I managed to fire it up yesterday evening and was purring like a kitten.

What I did:

-Turned the idle mixture half a turn out from what’s suggested

-Increased the valve clearance to 0.25 mm intake and 0.3 mm exhaust, as the B10 camshaft has more aggressive ramp profiles.

-Advanced 3-4 degrees from what’s suggested.

I don’t know whether all this helped, perhaps it’s only the advance. I will be turning the idle mixture back to manual recommendation and see if something changes, then I will proceed to changing the valve clearances back to what’s recommended.