On my Le Mans III I increased the main jet from 115 to 120 as I read elsewhere on the forum that it’s a good idea to do this when fitting K&N filters. Well my bike had these fitted when I bought it last year but the main jet had not been changed - I have done this now but worry it is actually running too richly. My question is, should I have adjusted the taper needles which are still in position 3? Any advice or thoughts much appreciated.

What makes you think it’s running too rich?

As I understand it, the main jet size only influences mixture once you are at 75% throttle or more.

Have a read of the Dellorto tuning guide, which is available on line.

http://www.thisoldtractor.com/mg_manuals/dellorto_manual_a_guide_1.1.pdf

Well, it’s a long story… Initially I had sticking chokes, which I fixed, and I stripped and cleaned the carbs and also installed Dynatek ignition. But soon after I found the plugs fouling quickly - especially on the left, and the exhaust exit heavily sooted up. I had put Iridium BPR7EIX plugs in, which may not have been suitable for the local driving I was doing. I have gone back to BP6ES and it’s running well but that may just be because they are non-fouled plugs and in due course will soot up and misfire - so wracking my brain for possible alternative reasons why I am getting such fouling I wondered about the needle taper: when I stripped and cleaned the carbs I saw the needles were on the 2nd position so I put them to the 3rd as per manual. I noted also the was 268 not 265. I have the Dellorto manual but couldn’t see I’d done anything different apart from go up a size on the main jet. I’m afraid it’s beyond my skills to properly understand the finer points of carb tuning and beyond altering needle height and re-fitting the smaller main jets again I can see I may have to take to a dyno tuning garage. But in anycase I will run the bike for some miles and report back how she is going!

So the bike runs well at speed but pops and farts at tickover or coming off throttle only on the left side. Plugs nice tan brown.

Bearing in mind I have ultrasonically cleaned the carbs twice and fitted a complete new ignition system…

Things to check / recheck:

- check for air leak at manifold

- Check for exhaust leak

- Check tappet gaps

- Check compression

- Check static and strobe timing

- Check carb balance

My worry now is that I have a sticking exhaust valve, but surely that would be an issue at all speeds not just tickover?

Any other suggestions guys for what I could look for or check?

Have you tried turning the mixture screw out a bit more on the left carb, (more fuel) to see if that sorts it?

On my 1000s one screw is about a quarter of a turn further out on one side to stop it spitting when you just open the throttle

If it were me I’d think of going back to stock and go from there.

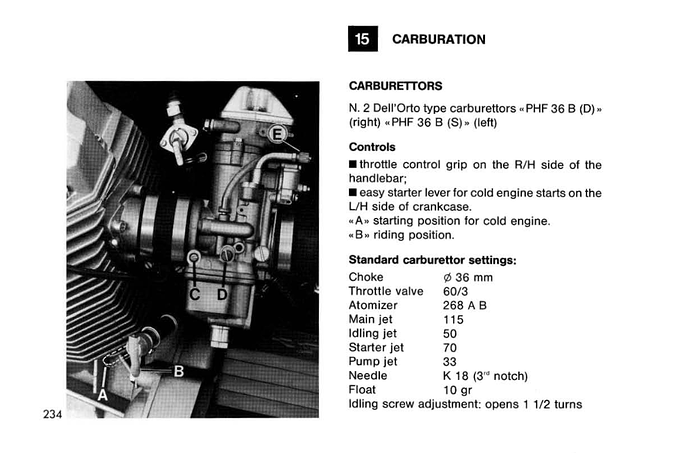

From LM3 manual from thisoldtractor site -

It also says Bosch W5D for the plugs, this equates to NGK BP7E / BP7ES (not 6, which is a different heat range)

Well Gents, I am making progress - I completed all on my list - tappets were well adjusted, timing spot on, compression 175 on both and no evidence of air or exhaust leaks. I took the LH carb off and checked and all was good inside but I gave extra blow throughs of the idle jet as it could indeed have been a fuel starvation on idle. On refitting with the screw turned out 1 and a half it was still popping, but opened out 2 and a half it stopped - so I must have had a speck of grit blocking it as even opening out fully didn’t help before!

Only issue now is getting it to tickover nicely - if I blip the throttle the revs stay up at 3k and come down slowly. I’ve ordered some new throttle cables and will rebalance in case one is sticking - thanks as ever for the advice!

The revs coming down slowly could be the throttles out of synch, it’s worth investing in a pair of vacuum gauges and sorting it properly, (Davida ones are good) other methods are available,

![]()

![]()

On refitting with the screw turned out 1 and a half it was still popping, but opened out 2 and a half it stopped - so I must have had a speck of grit blocking it as even opening out fully didn’t help before!

I had this for a long while, 2 & 1/2 turns or so, then I discovered maybe all the jets were partially blocked, lashed out for new set of jets, hey presto back to 1 1/2 turns on both screws and the starter enrichers (choke) made it VERY rich so a winter only use, in summer will just flood and won’t start.

Only issue now is getting it to tickover nicely - if I blip the throttle the revs stay up at 3k and come down slowly. I’ve ordered some new throttle cables and will rebalance in case one is sticking - thanks as ever for the advice!

Had this happen also, also on the R80, and it turned out the reason is because the slide stops are a bit too high, in other words, to make it idle, screw out the mixture screws more, which enables the slides to be lower then the throttles behave properly. Again, it changes again with new jets but was much easier to set up because everything is working properly then.