Hi Can you help?

I’ve recently purchased a nice 1969 Ambassador and spent quite a few nights getting it ‘right’ Everything works as it should and the bike rides and runs spot on. I know this subject has been covered at great depth over the last few years but I was just wondering what the present situation is concerning chrome bore replacements.

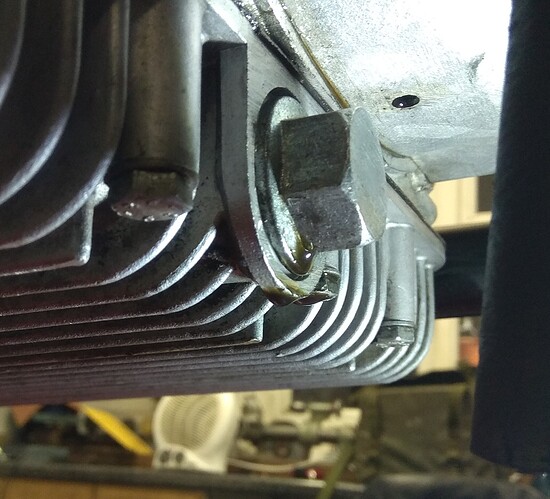

I’ve have had the heads off both sides and had a look at the bores. They both look fine, with no flaking, I am very aware through looking at previous posts that I need to do something about the ‘Ticking time bomb’ situation and replacement barrels and piston are no longer avaliable.

What I need to know is has anybody else done the same recently at what is the best course of action?

Many thanks Dave

The “go to” solution is a Gilardoni kit, which comes with barrels, pistons etc. But they only make batches periodically so you can’t always find them.

I couldn’t find any when I did my 850GT last year. It was on 50k miles and had no apparent issues but as I was furloughed I decided to take the heads off. There was a small area at the very top on one side where some chrome had come off.

I sent my barrels and pistons to Langcourt Engineering who stripped the chrome and replated with Nikasil. Total cost was probably about 75% of a Gilardoni kit.

Rings for the loops can be hard to find, so my backup plan was to fit T3 pistons. But Teo Lamers managed to find me 2 sets.

Ian

Thanks for the quick reply Ian.

50k without too much wear …mine are at 22k maybe the chrome barrels do get a bit of bad press. Still need doing. The real shame is the bike has one of the sweetest engines I have heard, really doesn’t sound like a Guzzi . I have contacted Langcourt Engineering ad I’m waiting to hear from them. My only concern with that route would be that I read in Guzziolgy that it’s important to replace the rings as there is slightly more resisitance with nikasil so you need rings which match the coating. I would prefer to go down the Gilardoni route but I think it’ll be a long time before they make any more.

Did you have any issues with Langcourt and what was the turn around time like?

Cheeers Dave

I think there are 2 issues with chrome bores, either wear or wholesale flaking. I’ve heard that the latter is more likely with motors that don’t get used much or have been stored in damp conditions. I don’t know if it’s true, or whether it’s based on how well the coating adhered when first applied. Mine was certainly showing signs that it was getting thin. Will try and find some photos.

I caught Langcourt just as first lockdown was relaxing so they had a backlog. It took about 6 weeks and cost £330. Normally they say about a fortnight. No problems so far, but it’s only done about 1000 miles.

Rumour is that a batch of Gilardoni barrels is imminent, so maybe worth calling round the usual suppliers.

Yes, you need to use correct rings. I’m not an expert but was told that the ones I have are good for Nikasil.

Ian

Thanks for the heads up on the arrival of the Gilardoni barrels. Apparently they’re due in the next few months, so I think I’ll wait. Looks like I’m going to be off the road for a while now as the throw out bearing on the clutch push rood has decided to pack up.

The little flat bearing? Pretty sure you can change that with the gearbox in place although may need to take a few bits off to get at it.

Yep. ‘Guzziology’ states that the gearbox housing needs to be machine to take the later 5speed thrust bearing which is a needle and 2mm bigger. After googling a while the ‘This old tractor website’ showed me the way with a all the info and bearing numbers…job done.

I am going to pull the gearbox out in the next couple of weeks as there is still a small leak from the bell housing hole. Apart from the JBing the welsh plug, changing the gaskets and the seal is there anything else I should be looking at? Any tips would be greatly appreciated.

thanks Dave

I assume it’s engine oil leaking rather than gearbox oil? If it’s only a little bit, I might be inclined to leave it as it won’t get on the clutch.

I have never done the rear crank seal on mine so can’t really add anything useful on that, but maybe worth making sure it’s not running down from the breather oil return. This comes in at the top and the pipe goes between the flywheel and the block. I have heard they can leak where the hose joins underneath the breather, so the oil runs down the outside of the pipe.

Thanks for the heads up.

I’m pretty sure that the seal has blown. At standstill it leaks very little and i thought for a while I’d got away with, after all it’s a 53 year old bike and it’s bound to leak a bit. (I’m 58 and I sometimes weep a bit). After a fairly long shake down ride, around fifty miles, and within a stones throw from home I decided to explore a little further up the rev range and that’s when the clutch started to slip. Once back to pootle mode it was fine

.

So I intend to get the gearbox off and have a look. It’s quite alot of work for a 12 quid seal but I won’t be happy until I know for sure. Only part I’m a little concerned about is linning up the clutch and holding the flywheel both of which need special tools. I bet there’s a get round but I can’t find it.

I’ve attached some pics ..again any opinions much appreciated.

Thanks Dave

I rebuilt the clutch etc on my spada a few years ago and managed it without ny special tools. To lock the flywheel, I used a pice of wood wedged in the starter hole for some bits and a 13mm ring spanner on one of the bolt heads locked against the studs on others.

As for lining up the clutch, I did it by eye. Get it as close as you can, then I wound down the flywheel with some studs and nuts. There are a few holes in the outer flywheel where you can see the teeth engaging in the splines, I just nudged them into place with a fine screwdriver as I clamped it all down.

You can get at the clutch on the Loop frame without removing the engine. Once you’ve pulled all of the back end off, and all the engine bolts except the front lower you can then pivot the rear up until there is just enough room to pull the gear box off.

I’m pretty sure engine oil can’t get onto the clutch, although I stand to be corrected. But gearbox oil can.

If it’s not been used much recently, it could be hanging up on the splines, as my Spada was. The famous “white spirit wash” sorted it and the slip has not recurred for 6000 miles.

I did the clutch on my loop last year. Butch is right that it can be done with the engine in place, although it’s only one more bolt to take it out. The only thing that stopped me taking the motor out was not having enough space for it. It would have been nice to clean and repaint the frame tubes at the front as I did at the back.

Don is also right - you can do it without the special tools if you know how to improvise. I was able to borrow everything except the tool to compress the springs, but managed to improvise something for that. The gearbox input boss will align the 2 friction plates to each other, but you also need to make sure they are centred in the flywheel and that the springs are in the pockets. There are also some marks to time all the parts to the engine, but this is less important on a loop as the ignition timing marks are not on the flywheel.

I’ll find a link to a video of Nick Adams taking his Eldo gearbox out.

Ian

Wow what a great forum.

I’m new to this whole Guzzi thing but I’m no novice I’ve rebuilt everthing from an MZ to a 180 Jota. I’m pretty sure it is engine oil just by the feel and smell, either way it’s gotta come apart. I knew I was going to have to work on the bike when I bought it as there was a pool of oil under it. At the time I had a choice of this bike or a more sorted 850 with everthing done, head or heart choice and I’ve taken a leap of faith and went with the prettier bike.

I’ve watch Nick Adams taking his Eldo apart and now it’s my turn to have a go…I’ll let you know how I get on.

Thanks Dave

… the state of my back. So much easier to leave it in there than try and pull it out - I was doing the job on my own.

It must be tricky getting the clutch springs back in place with the engine in the frame. When I did mine, I stood the engine on its nose so the springs sat upright.

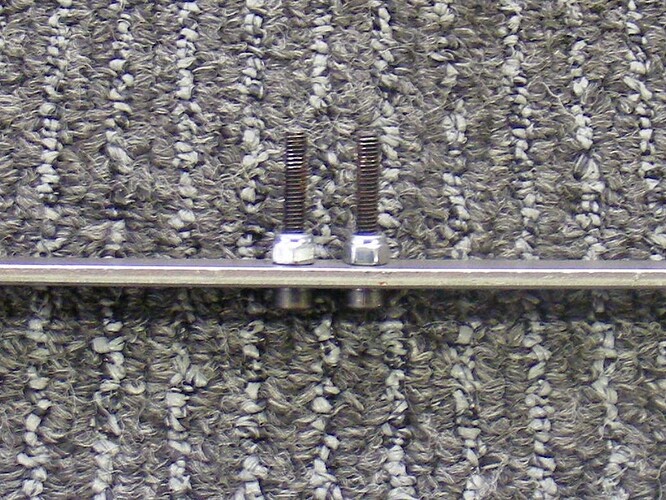

This is how I compressed the springs. Three longer bolts in the holes and wind the nuts down to compress the flywheel. Keep an eye on the outer plate notches to make sure they drop ino their slots.

P3210223 by Don West, on Flickr

https://m.youtube.com/watch?fbclid=IwAR2N6M10QodQouyC0bZUWp7Q2zB5GUBMfnGePzXsQpYXyODpjq-f-MhbK8A&v=wM8ZyXEI_fQ&feature=youtu.be

Hopefully this is Nick Adams’ video, although it sounds like you’ve already found it.

He’s also got some good riding videos around Canada. I wouldn’t take my loop some of the places he goes, although I’m not too precious about it!

Yep I’ve had a look…he sure works fast. All went fairly well tonight. Whoever ‘Restored’ the bike in the past had a bit of a habit of mixing metric up with imperial, bit of a pain. Other horrors were petrol line just pushed onto spigots and builders foam squirts under the dynamo cover, still the paint is pretty.

I’ve got to a point now where I need to make up a tool for removing the swinging arm. so I have another go in a couple of days. I’ve also removed the crankcase breather( used to be call a fru fru valve when I worked on 2cvs) What is the best way to wash this out or should I replace it? Anyway so far so good.

I think I read somewhere they could be glued in with something.

My Loop is the only Guzzi where I’ve changed the clutch with the engine still in, but I don’t recall this being a problem. I suppose the engine was canted at about 45 degrees at least.

I managed to locate some Gilardoni barrels from TLM (Teo Lammers?) in Holland. There a little on the pricey side at 400 euro a side. But before I order them is this right. are they left and right handed?

https://shop.tlm.nl/en/cylinder-compl-v7special-130202000010-moto-guzzi

Has anyone else ordered from them. This is alot of beer tokens I just want to make sure.