I think I may be opening a can of worms here. The V50 II has Bosch electronic ignition which looks well engineered in typical Bosch fashion. However it doesn’t seem to work well in respect of the advance curve. But I’m already getting ahead of myself.

The manual says that there are two marks on the flywheel “D” and “S” for the right and left tdc positions and also two marks indicating max advance for the two cylinders. None of those marks are present on my flywheel. So, I found tdc for each cylinder with a dial gauge through the plug hole and marked the flywheel with a paint pen. I then counted 4 degrees per tooth on the ring gear and marked 34 deg btdc for each cylinder. Please shoot me down if I’ve got any of this wrong, I’m new to this engine and I am going by the information I manage to glean here and there!

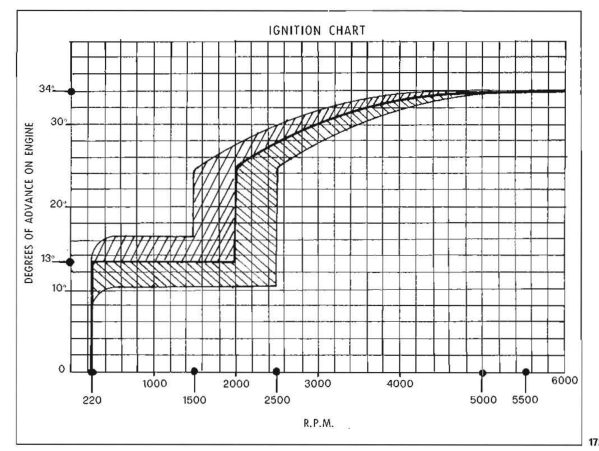

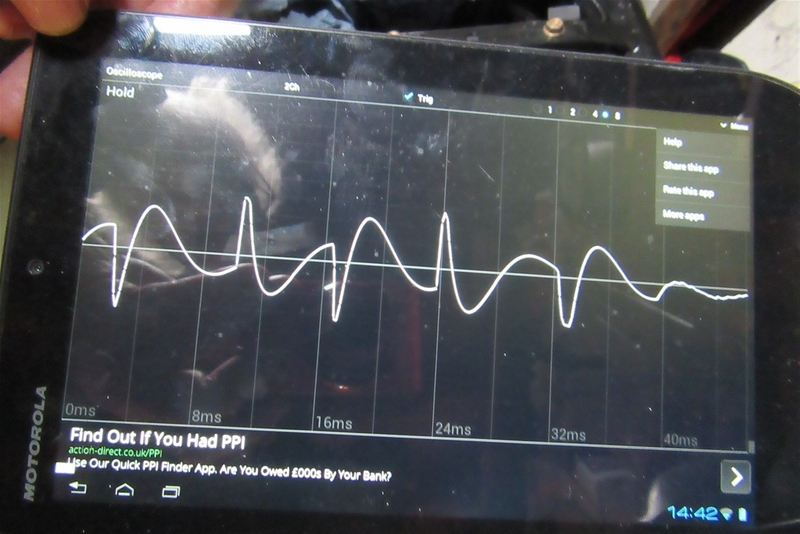

I now put the strobe on it and I found that at idle, the timing was around 10 deg btdc, which sounds OK to me. As I increased the revs, there was no advance until I reached about 2500rpm, when it suddenly jumped to about 25 deg btdc, causing the engine revs to shoot up. It’s not easy to check what happens after this, but the timing actually retarded slightly before advancing again (more smoothly) up to max at around 3500rpm. The max was different on the two cylinders by a few degrees.

On the road, this means that the bike either surges forwards or dies a death at about 2500 rpm. It can feel like a huge flat spot as you accelerate. It can also be a pain in the neck if you are doing a U-turn.

The diagram in the manual indicates that this is correct for this ignition and if I’m reading it correctly, there is quite a wide “tolerance band” - mine was towards one end of this band. I gather that the change to points ignition on the V50 III was to cure this problem (?)

I have found two after-market electronic systems on the internet from Sachse and “Silent Hektik” - both located in Germany. Both look good and both are eye-wateringly expensive. They both come with multiple advance curves, switchable and one (Silent Hektik I think) is programmable. In both cases it should be possible to select a curve which is a big improvement on the original Bosch system.

Another consideration is that apart from any shortcomings in the advance curve, the Bosch system is almost 40 years old. I’m not sure that I’d trust it for touring abroad unless I was carrying a spare. Spares do appear on ebay, but at silly prices for a second hand bit of 40 year old electronics!

So, has anyone any experience of the Sachse or Silent Hektik system? Any other comments gratefully received!